Rendering Lard

Not long ago I had a hog processed and had the butcher keep the lard for me. I had the lard ground as it saves the step of having to cut it up into small pieces! The process of rendering is simply melting the fat so that it separates from the rest of the "impurities" (pieces of meat, bone, or whatever else was inside the hog). Also heating and melting helps remove the water - while technically you can never remove all the water you do want to evaporate as much as possible. I use a large electric roaster, some people use a double boiler, a cast iron dutch oven, and I am sure there are numerous other methods. Regardless what you want to achieve is as follows:

- Melt it low and slow (200-250 degrees F)- if you burn it then the lard will have a smokey or pork like flavor which may be find for deep frying but not if you are going to use it for pies

- Heat it evenly - this is why smaller pieces are advantageous as is heating methods where the sides of the pan do not get overly hot (traditional pans for heating water will do this and once again cause burning).

- Filter it well to remove all the impurities - it is said that lard won't mold but it will go rancid that if you there is mold then there were impurities. Also those impurities will impart undesirable flavors!

- The butcher put the lard in a large plastic bag which was then frozen advantage was that I did not need to render it right away

- However just tossing it in the roaster is a bad idea as the outside will begin to melt while the inside is still frozen solid! Just a side note but I tend to heat it up on my deck during the summer. I see no point in running both the AC and heating up the house at the same time. Obviously you have to be more careful about insects and watching to make sure things to fly into the pan!

- One option would have been to put it in the refrigerator overnight and let it thaw out on its own. However, I wanted to get the project done so I just put it on cutting boards and went after it with a large knife.

- Since the lard was already ground it was not that important to get them into really small pieces, however if your lard is not ground then cutting them into small pieces. The smaller the better as it will reduce the amount of time required to render!

- Simply start adding the pieces to the roaster! I try to keep the temperatures at 225 F.

- As time goes by the pieces will begin to melt, stir frequently so that the processes occurs more evenly.

- Eventually you will have a pan full of melted lard and cracklings

- First I filter with a colander, it quickly removes the largest pieces without clogging up.

- Some people will keep the cracklings, fry them, and eat them.

- I return the remaining oil to the roaster and heat it back up. Mostly to help with the next step.

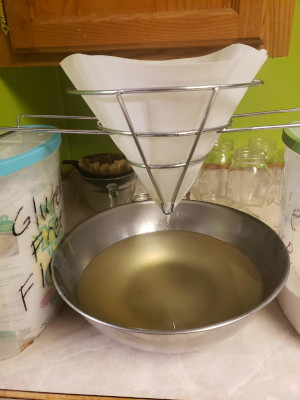

- I happen to have a "Fryer Filter Stand" and woven filters designed to filter oil (which is what lard is), I also use the stand and filters for maple syrup. I just run the lard through it and when it is hot it flows through quickly removing the remaining impurities. Cheese cloth will also work well but you may need 4-5 layers and I have also used coffee filters but they seem to clog quickly.

- The next step is to put in some type of storage container, I have read that metal containers react to the lard, I use mason jars. I first sterilize them by boiling in hot water right before putting the oil in, I wait just long enough for the water to evaporate out of the jar. I then fill and immediately put a new lid on. The lids have always sealed but I do store the lard in the refrigerator as an added precaution against any type of spoilage.

- Just a close up to demonstrate that at this point the melted lard is a yellowish/lemon-aid color

It will turn white once it hardens! With this particular batch I ended up with an excess of 1.5 gallons of lard. However, this came from a hog that was nearly twice as large as I usually get.